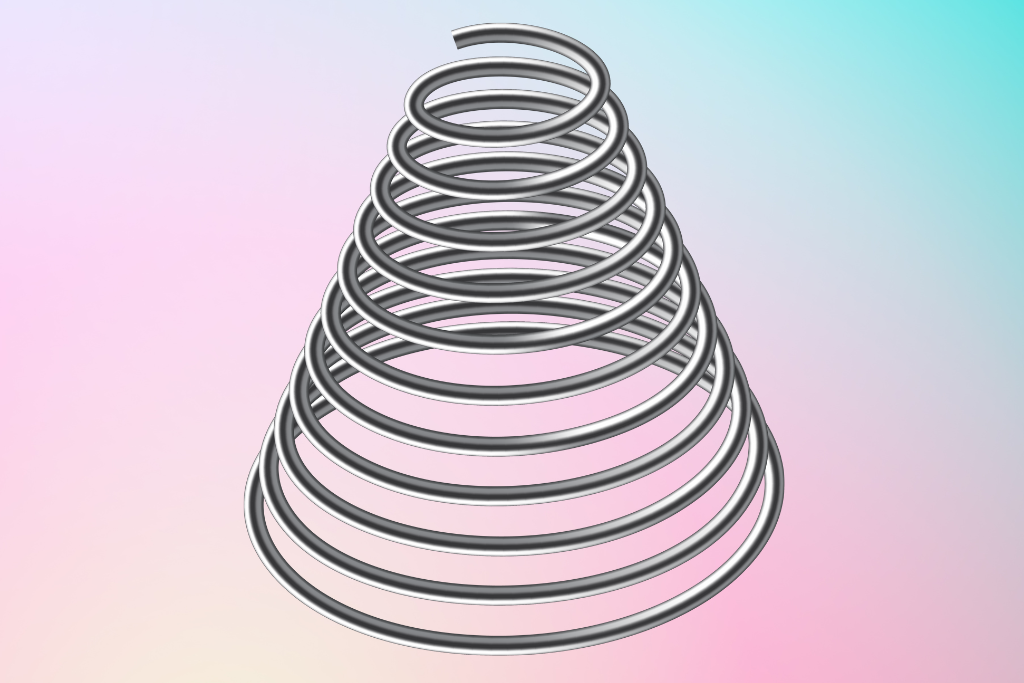

The Metal That Remembers is an alloy that can remember its original shape and keep it. It has the ability to undergo a reversible phase transformation and has unique properties. This article will discuss the properties of this material and its uses.

Shape memory alloy

Nitinol is a shape-memory alloy that has widespread applications in medical devices. It has high ductility and a high strain-hardening property, making it difficult to cut. Its ductility makes it easy to bend into a new shape, but it is difficult to reverse this process once the material is heated. This is because the alloy’s structure is martensitic and it changes to an austenitic structure when heated. As the alloy cools, the change in structure causes it to return to its original shape.

The shape-memory alloy has an extremely high transformation temperature. Its elasticity depends on how many atoms are in it and can be changed by making small changes to its composition. Nitinol is available in martensitic, austenitic, and superelastic formulations.

The most common shape-memory alloy is the nickel-titanium alloy. Its properties include good superelasticity, ductility, biocompatibility, corrosion resistance, and high strength. Although this alloy is expensive and difficult to work with, its properties make it an excellent choice for many applications.

Reversible phase transformation

The shape memory effect of nitinol allows for reversible phase transformation in this material. At high temperatures, the material changes to a cubic crystal structure, while at low temperatures it changes into a martensitic phase. This is known as the transformation temperature. At a certain temperature, the material completely transforms back to its original shape.

The change from austenite to martensite gives off a lot of heat, and the peak on a differential scanning calorimeter is often mistaken for the martensite peak. However, the austenite phase exhibits very high electrical resistivity, making it useless for determining the temperature of Nitinol.

Nitinol is used in medical applications where it can be inserted into tight spaces and then released to a larger size. For example, a Nitinol wire can be inserted into a narrow delivery tube and then heated until it reaches a desired set size.

Unique properties

Nitinol is an alloy made from nickel and titanium. It has special qualities that make it a good choice for a wide range of medical devices. In addition, nitinol is biocompatible, stable, and corrosive-resistant. Hence, it is often used for implantable devices.

One unique property of Nitinol is its shape memory. For example, if you bend a piece of nitinol wire into a looping ball and drop it into a bowl of hot water, it will immediately return to its original shape. This property makes it an excellent material for bending applications.

Nitinol is also different because it can stay in two different crystalline phases. These two phases give it its superelasticity. This means that Nitinol can retain its shape even after undergoing a traumatic event. This property, called the shape-memory effect, makes it a valuable material for use in a variety of applications.

Nitinol also has high fatigue strength, meaning that it can sustain up to eight percent of strain above its transformation temperature and still return to its original shape. Additionally, it is biocompatible and has good conductivity. It can be used in various medical applications, from stents to dental equipment. Its elasticity can be up to thirty times greater than that of ordinary metal.

Applications

Nitinol is a shape memory alloy, which means it can go back to its original shape after being bent or stretched. It has many applications in today’s technology, from medical devices to vibration damping. This article explores some of the more common uses of this material. We will explore the different types of applications and how Nitinol can be used in various fields.

Orthopedic implants, for example, are made of Nitinol. This material is more compliant than stainless steel and titanium, which makes it a superior choice for this purpose. Nitinol is also used in endoscopic procedures. Laser-cut Nitinol shafts are able to reach difficult-to-reach locations in the body.

Nitinol can be produced in large cast ingots. Then, it can be further processed to form ultrafine wires, which are thinner than human hair. This process requires precise control of the material’s physical and mechanical properties.